A British manufacturing firm has introduced technologies that “promise to revolutionise” drug testing in the medical and pharmaceutical sectors.

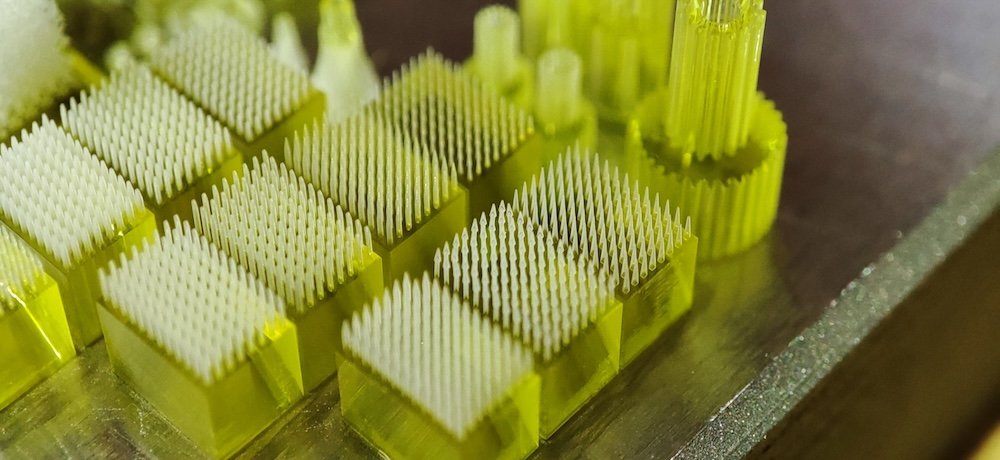

IPFL’s micro 3D printing services enable the production of intricate three-dimensional structures with previously unachievable resolution. With Projection Micro Stereolithography (PµSL) equipment produced by Boston Micro Fabrication, structures can be manufactured with dimensions as small as 40 microns and an overall resolution of two microns – about the size of a fine dust particle. IPFL is the only firm in Europe that currently offers this PµSL technology.

This level of resolution opens up the possibility of using 3D micro printing to create microfluidic channels for pharmaceutical testing products. These include organ-on-chip, body-on-chip and lab-on-chip devices, which can simulate key characteristics of human tissues on artificial products. Scientists at the University of Edinburgh have recently pioneered the design of a 3D-printed body-on-chip device that simulates how a drug circulates within human tissues and a miniaturised circulatory system.

IPFL’s PµSL printing processes could produce these chips in quantity, leading to the reduction or even the future elimination of animals in pharmaceutical testing.

IPFL’s experience and expertise with plastics contribute to microfluidics in the pharmaceutical field in other ways. The firm can also offer diffusion bonding services, where advanced polymers such as acrylic, COC (Cyclic Olefin Copolymer) and Ultem are fused at a molecular level under finely controlled temperatures and pressures.

Traditional 3D printing and bonding methods can cause contamination or compromise the integrity and accuracy of microfluidic channels. These new processes allow the fabrication of clearer, cleaner, and more durable microfluidic systems, which provide the accuracy and repeatability needed for scientific research.

Adam Bloomfield, additive manufacturing manager at IPFL, said: “This unique combination of high-precision fabrication and advanced bonding techniques positions IPFL as a leader in the field of microfluidic device manufacturing, ready to meet the evolving needs of the pharmaceutical and biomedical industries.

“Our commitment to innovation and quality ensures that we continue to offer our clients the very best in microfabrication solutions, driving forward the possibilities of medical research and diagnostics.”