Flex PCBs Handle Electromagnetic

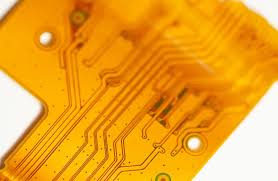

A flexible circuit board is a type of printed circuit board that incorporates conductive material in a flexible base. The conductive material is normally copper foil, but this can also be other metals. The copper foil is then etched into a specific pattern to form the electrical conductors. A coverlay is then applied to protect the copper and make it resistant to moisture and dirt.

Flex PCBs have a number of advantages over traditional rigid PCBs, and one major benefit is that they are much lighter. This is due to the fact that they use incredibly thin bases made of polyester or polyimide materials. They can be as thin as 12 to 120 microns thick.

The base material is what gives the flex circuit its primary physical and electrical properties, and it is also the core of the laminate. A variety of different base materials are used, but copper foils account for the majority of flex circuit applications. The foils are bonded together with various adhesives, which vary from acrylic to epoxy.

In addition to the base materials, there are several other options that can affect a flex circuit’s cost. For example, if the board needs to be shielded from electromagnetic interference (EMI), this can add quite a bit to the final cost. In many cases, this requires a three-layer shielded design. This additional layer raises the overall thickness of the flex circuit, which can limit its bending capabilities. It is important to consider this when designing a flex circuit.

How Do Flex PCBs Handle Electromagnetic Interference?

Another factor that can increase a flex circuit’s cost is the selection of the copper plating method. Panel plating uses a thin film of copper to coat the entire surface of the flex circuit, whereas button plating applies copper only to the vias pads. Panel plating is cheaper, but it can limit etch yields in some situations. In contrast, button plating allows the manufacturer to manage copper thickness and maximize etch yields in intricate etch patterns.

Lastly, the type of flex pcb design can also affect manufacturing costs. It is generally good practice to keep conductors away from the edges of the flex PCB to prevent stress concentration during bending. It is also advisable to offset traces when possible to minimize stress concentration.

In addition to the aforementioned factors, it is always a good idea to use a flex pcb calculator from PCBway to determine the price of your circuit board. This tool will help you get the most accurate quote for your project. This way, you can be sure that your flex circuit is within your budget and that it will be built correctly. Additionally, you can use the calculator to determine whether the flex circuit meets IPC standards and any other required criteria. Finally, it is also a good idea to ask PCBway to do some electrical test on your flex circuit to ensure that nothing went wrong during manufacturing. The test will check for things like short circuits and cuts in traces, which can lead to failure of the flex pcb.