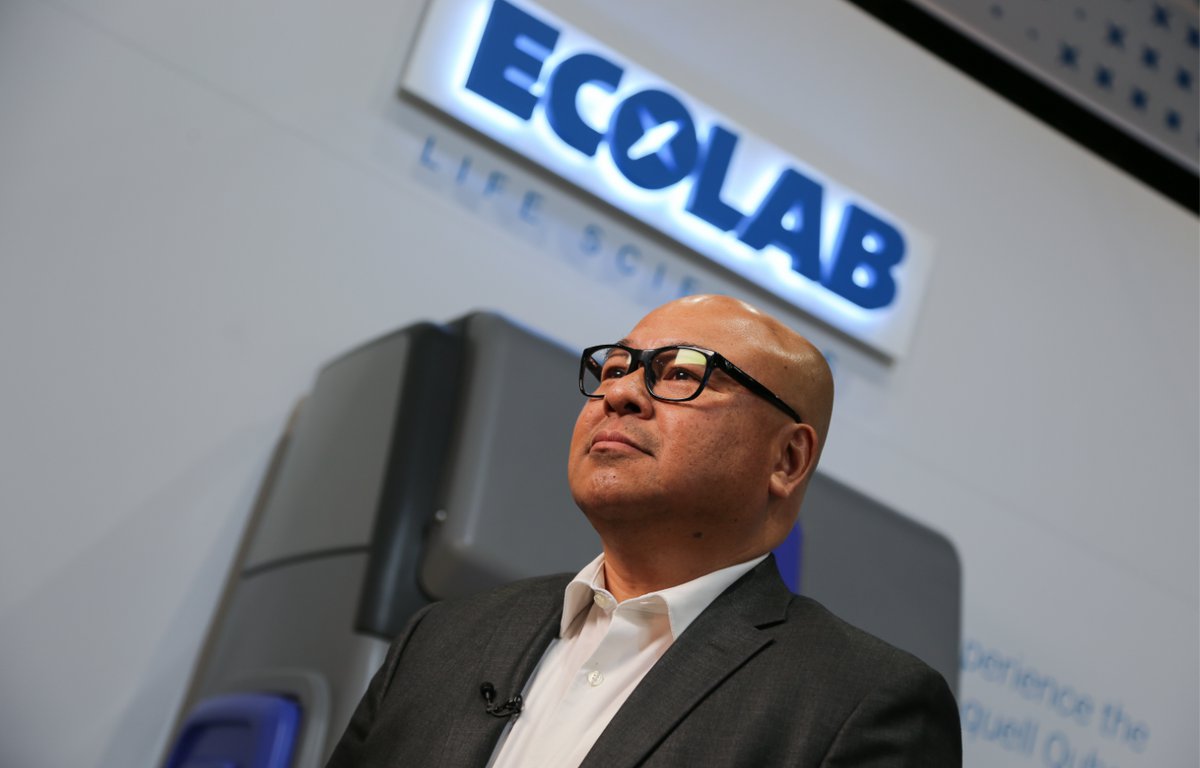

We caught up with Purolite’s Felix Solamo to look back on Bio International 2024 and what it meant for the Company.

EPM: What new products or innovations did your company showcase at BIO 2024?

Felix Solamo: At BIO 2024, Purolite announced a major product innovation in affinity chromatography. Our new protein A resin, DurA Cycle A50, promises to address key challenges facing the biopharmaceutical industry. Our new offering represents the culmination of extensive research and development, and collaboration with top experts in the field, and we were delighted with the significant impact it has made at the show.

BIO International provides the perfect platform for showcasing this major product launch to a global audience of industry leaders, innovators, and stakeholders. With its networking opportunities, educational sessions, and access to potential partners and customers, the event offered us a prime opportunity to generate buzz, build brand awareness, and drive engagement around our new solution.

Attending the event also aligned perfectly with our strategic objectives of expanding our market presence, forging valuable partnerships, and staying at the forefront of industry trends and developments. By taking part in this event, we have demonstrated our commitment to driving positive change within the sector.

Alongside our new product launch, Ecolab shared key updates surrounding its new Life Sciences sector and its product portfolio across active pharmaceutical ingredients (APIs) and excipients, milling media, and downstream purification.

EPM: What has Purolite achieved from the event?

Felix Solamo: The biopharmaceutical industry is very much a people-focused industry, and collaboration is key, so we’re always looking for new ways to engage with delegates who attend BIO International and nurture relationships across the value chain. There’s nothing like meeting people face-to-face to discuss projects and help build deeper, more meaningful relationships. This way attendees of BIO get a real feel for who we are, the innovative solutions we provide, and the culture of our business.

The main objectives for participating in BIO include engaging with current customers, meeting prospective new customers interested in our solutions, and presenting Ecolab’s capabilities and investments in Purolite. The event is a regular fixture on Purolite’s events calendar, presenting an excellent opportunity to introduce our offering to a broader audience

EPM: What challenges are currently facing the pharmaceutical market, and how is your organisation addressing them?

Felix Solamo: The pharmaceutical industry is currently facing several challenges, particularly surrounding sustainability during drug production.

Sustainability has become a critical consideration in recent years. Purolite is focused on how decisions made during downstream processing can help mitigate environmental impacts, conserve resources, and ensure economic viability while meeting sustainability-related regulatory requirements. To address these challenges, we are implementing innovative practices and technologies that minimise waste and energy consumption, thereby reducing our environmental footprint.

EPM: Can you discuss any plans for expansion or market growth in the pipeline?

Felix Solamo: In response to customer and market needs, Ecolab has not only developed innovative new products but has invested in additional manufacturing capacity to increase global resin supply and provide increased supply security.

Through a heavy and continued investment from Ecolab, we are investing in dual-continent supply capabilities. This means that as our customers’ production scales and grows, we can provide the necessary volumes to our global customer base from strategically located manufacturing locations. This enhances supply chain reliability – especially during challenging times, such as the pandemic – and enables Purolite to strategically locate its manufacturing operations close to key customers.

This investment into the additional manufacturing facility will enable Purolite to continue to meet market demand.

EPM: What sets your company apart from competitors in the pharmaceutical industry, and what value do you offer to your customers?

Felix Solamo: Purolite utilises a unique, patented approach to its resin manufacturing – we call this Jetting technology. For decades, the chromatography industry has relied upon traditional “batch emulsified” manufacturing processes. This emulsified technique includes additional steps to achieve comparable purity to Jetting, increasing lead time for customers. Purolite’s jetted resin reduces lead times through fewer development steps, provides true lot-to-lot consistency, and is more environmentally friendly, using fewer harmful solvents.

In addition to its patented Jetting technology, Purolite has partnered with Repligen to combine Repligen’s expertise in ligand development with Purolite’s base bead technology. Collaborative efforts with partners like Repligen have led to the development of ligands, including our novel Praesto Jetted HipH resin which shows remarkable promise in purifying unstable molecules, enhancing recovery rates, and reducing product loss. This innovation is viewed as a potential game-changer in the industry and is the direct result of leading technology providers partnering to deliver innovation to the market.