cost factors in circuit board assembly

Circuit board assembly plays a critical role in determining the reliability of electronic products, influencing their performance, longevity, and overall quality. As the foundation of electronic devices, circuit boards must be assembled with precision and care to ensure optimal functionality and durability. Here’s a closer look at how circuit board assembly impacts product reliability:

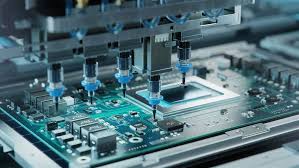

Component Placement and Soldering: Proper component placement and soldering are essential for reliable electrical connections between components and the circuit board assembly. Misaligned components, insufficient solder, or soldering defects such as cold joints or solder bridges can compromise connectivity, leading to intermittent failures or complete malfunctions. By ensuring accurate component placement and high-quality solder joints, manufacturers can enhance the reliability of circuit boards and minimize the risk of performance issues.

Quality of Materials and Components: The quality of materials and components used in circuit board assembly significantly influences product reliability. Low-quality or counterfeit components may have inconsistent performance, shorter lifespans, or higher failure rates, jeopardizing the reliability of the entire electronic system. By sourcing components from reputable suppliers and conducting thorough quality assurance checks, manufacturers can mitigate the risk of component-related failures and improve product reliability.

What are the cost factors in circuit board assembly?

Assembly Processes and Techniques: The assembly processes and techniques employed during circuit board assembly can impact product reliability. Automated assembly methods, such as surface mount technology (SMT) and reflow soldering, offer greater precision and consistency compared to manual assembly methods, reducing the likelihood of assembly defects and improving reliability. Additionally, advanced techniques such as selective soldering and conformal coating can enhance the durability and environmental resilience of circuit boards, further improving reliability.

Environmental Factors: Circuit boards are often subjected to various environmental stresses and conditions during operation, including temperature extremes, humidity, vibration, and shock. The assembly process must take these factors into account to ensure that circuit boards can withstand harsh environments and maintain reliable performance over time. Proper material selection, design considerations, and assembly techniques can enhance the ruggedness and environmental resilience of circuit boards, minimizing the impact of environmental factors on product reliability.

Testing and Quality Control: Rigorous testing and quality control measures are essential for identifying and addressing potential reliability issues during circuit board assembly. Electrical testing, functional testing, and environmental testing help verify the integrity and performance of circuit boards under real-world conditions, ensuring that they meet specified reliability requirements. Additionally, comprehensive quality control processes, including inspection, validation, and corrective actions, help prevent defects and ensure that only high-quality products are shipped to customers.

Lifecycle Considerations: Product reliability extends beyond the initial assembly process and encompasses the entire lifecycle of electronic devices. Factors such as maintenance, serviceability, and end-of-life considerations can impact the long-term reliability and sustainability of electronic products. Designing for reliability, incorporating robust materials and components, and implementing proactive maintenance strategies can prolong the lifespan of electronic devices and enhance overall reliability throughout their lifecycle.

Customer Satisfaction and Brand Reputation: Product reliability directly influences customer satisfaction and brand reputation in the marketplace. Reliable electronic products earn the trust of consumers, leading to repeat purchases, positive reviews, and brand loyalty. Conversely, product failures due to reliability issues can result in customer dissatisfaction, warranty claims, and damage to brand reputation. By prioritizing reliability in circuit board assembly, manufacturers can strengthen customer relationships and build a reputation for quality and reliability in the industry.

In conclusion, circuit board assembly plays a pivotal role in determining the reliability of electronic products. By ensuring accurate component placement, high-quality soldering, sourcing reliable materials and components, employing advanced assembly processes, considering environmental factors, implementing rigorous testing and quality control measures, and addressing lifecycle considerations, manufacturers can enhance product reliability and deliver electronic devices that meet the expectations of consumers for performance, longevity, and quality.